ACMA 780

orCall +961 5 437 555

Description

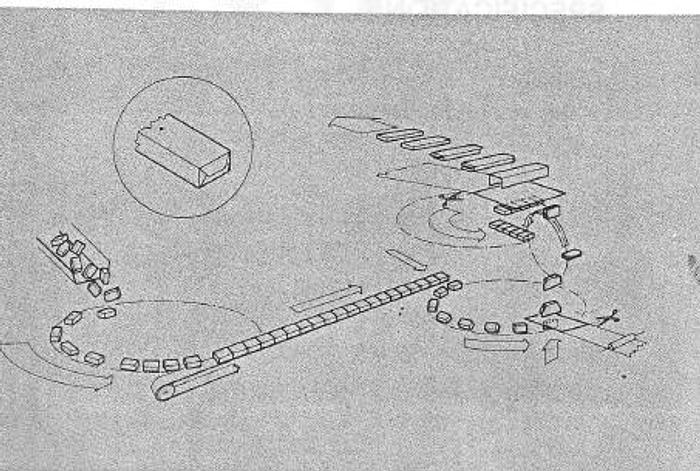

The ACMA Model 780 Candy Wrapper is a compact high-speed packaging machine quickly and easily adaptable to different shapes and types of products.

Candies are wrapped individually on an edge or flat, then collated, and finally wrapped in stick form in many different packaging styles.

- Solid Hard or hard-filled candies without alteration to the machine

- Suitable for 24-hour operation

- Circulating lubrication

- Applicable for hard products not requiring exact package dimension

- The operation is safe, and upkeep is kept to a minimum.

- All parts are easily accessible.

- The machine consists principally of the two conveying discs, the wrapping stations of the single candies, and the formed sticks.

- A separate integral vibrator is included in the disc feeding system.

The machine is equipped with the following extras:

- Tear-tape attachment for the outer wrap.

- Photocell for print registration of the outer wrap.

The single candy wrap is not sealed but folded and held under compression during the formation of the stick; there is no possibility of candies becoming unwrapped during this operation.

The candies are kept dry during the operation by heat from a lamp supplied as standard equipment.

*For more details, check the manufacturer's catalog of the machine below

Specifications

| Manufacturer | ACMA |

| Model | 780 |

| Condition | Refurbished |

| Stock Number | L244 |

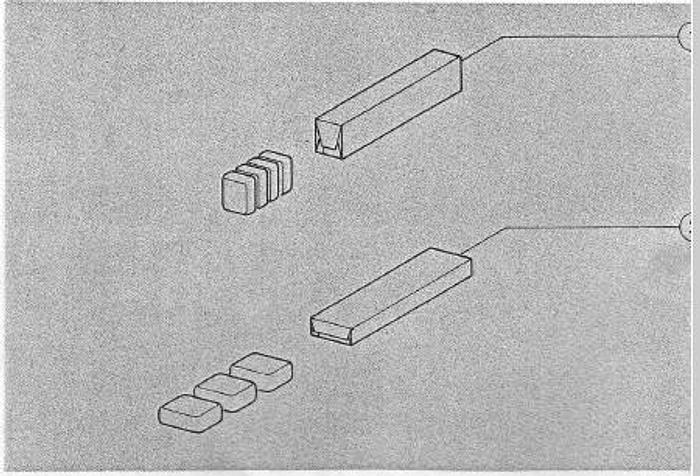

| Product wrapped | rectangular or square candies, solid or filled |

| Wrapping Technique | Acma 780 wraps rectangular or square candies and groups and overwraps them into sticks |

| Wrapping Style | 1) Set to Square or rectangular products packaged flat in double-point end fold style.. 2) Can be adjusted to: Square and rectangular products, packaged on edge in double-point end fold style |

| Wrapping Material | Normal wrapping of the single candies is with cello, while the outer wrap is normally coated with metalized paper. |

| Output | 250 pcs/min and 5 sticks/min |

| Lubrication | Circulating lubrication in oil-tight housing |

| Infeed system | Double Disc Feeder (for higher speeds), Product pusher and elevator, Extra feed hopper, Roll feed outer wrap, Candy wrapping, Outer wrap feed and product discharge |